In order to be able to offer the implementation of the laboratory-scale results in a production setup to our project partners and the industry, a galvanic line was developed and built. The combination of integrated measured value acquisition and the possibility of fully automatic operation together with the characterization possibilities available in our company (ESEM, AFM, X-ray diffraction, GDOES and FTIR) gives optimum conditions for determining the correlation between deposition parameters and layer properties.

Processes:

- Substrate pretreatment

-

- Coating of substrates

- DC methods

- Pulse and reverse pulse current methods

- Deposits without external current

- Coating of substrates

-

Applications:

- Preparation of surfaces with high hardness by chrome plating or nickel plating

- Decorative layers of gold or copper alloys

- Corrosion protection by zinc galvanizing, phosphating and anodizing

- Smoothing of surfaces by electrochemical polishing and deburring

- Application of micro and nanostructures (e.g. printed circuits)

Specifications:

- 12 PP tanks, 24L (300 x 200 x 400 mm)

- 6 baths equipped with heaters

- Data logging (with Labview)

- Operation by hand or automatically

Additional equipment:

- ultrasonic bath

- filter pumps (PVDF, PP)

- DC generator

- pulse rectifier

Sample Requirements:

- max. length: 250 mm

- max. width: 200 mm

- max. thickness: 75 mm

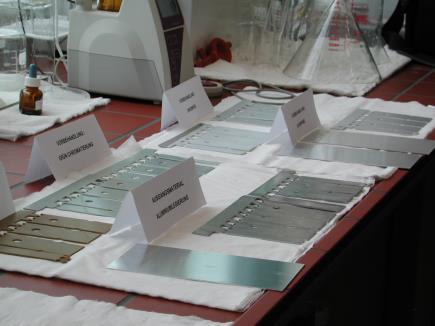

Examples of coated substrates

Examples of substrate pre-treatment (replacement of chromating)