Strategic Projects

ELCHEM II

(Bio-)sensors play an increasingly important role in our networked world. Since three of the human senses can already be detected by sensors (hearing, seeing, feeling), the project will create the possibility to also detect the sense of smell by means of sensors. By coupling optical (SPR) and electronic methods a setup will be established, which will be able to characterize odours by means of pattern recognition and the embedding of odour proteins and odour receptors.

The most important research points are:

- Surface Treatment and Biofunctionalization

- Optimization of stability by means of passivation layers

- Construction and networking of a suitable measurement setup

- Expression and modification of odour proteins

- Construction of membranes on the detection platforms

- Implementation of olfactory receptors

Project Manager: Philipp Fruhmann

FTiBa

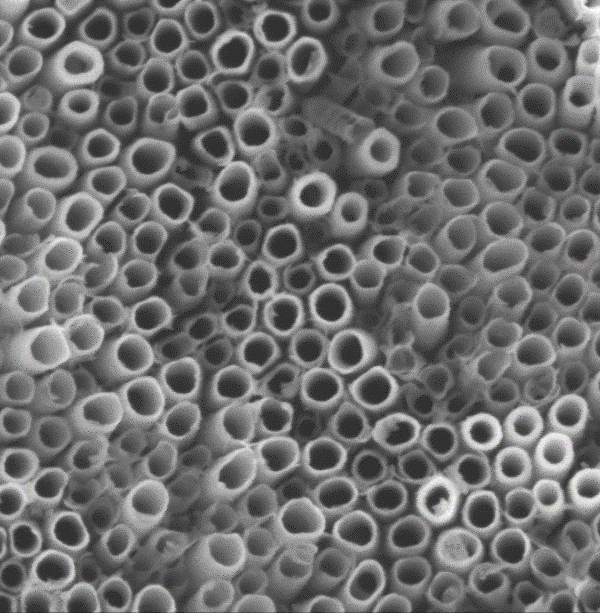

Surface modification of titanium-based implant material

Both micro- and nanotopography influence cell interaction. To influence that it is possible to nanostructure the titanium surface by using electrochemical methods. The self-organization of the titanium oxide can be controlled by the manifold variation possibilities of the manufacturing conditions. The topographical change thus opens up the control of cell interaction in favour of the human organism. On the one hand, the bone-implant interface is additionally enlarged and on the other hand, the self-organized cavities can be used as nanocontainers for antibiotic alternatives. By filling the nanotubes with antibacterially active substances, diffusion-controlled long-term protection can be achieved starting from the implant surface.

We deal with the following questions

- Nanostructuring of the titanium surface

- Nanocontainer- Drug Delivery System

- New antibacterial coatings

- Inhibition of biofilm formation

Project manager: Tzvetanka Boiadjieva-Scherzer

biglu

Biomimetic adhesives

The BIGLU project focuses on the development of bio-inspired adhesives. The model is an adhesive synthesized from mussels, based on proteins with the central molecule catechol.

The following questions will be addressed:

- Adhesion of the polymer to different surfaces

- Cohesion within the polymer

- Bonding strength under dry and wet conditions

- Influence of different metal ions on cohesion and adhesion

Project Manager: Markus Valtiner

SOXFUCELLS

Solid Oxide Fuel Cells (SOFCs) are an emerging technology for clean energy conversion, capable of utilizing a variety of different fuels (hydrogen, natural gas, biofuels, …) to supply electrical energy. On the way to a broad application of SOFC technologies, cathode performance and its degradation are two of the main remaining obstacles. Advanced experimental methods supported by defect chemical modelling are applied to promising cathode materials to identify and clarify degradation mechanisms and to investigate the oxygen exchange kinetics on the cathode surface.

Main research questions are:

- Intrinsic and extrinsic degradation phenomena

- Oxygen exchange reaction mechanisms

- Correlation of oxygen exchange kinetics and defect chemistry

- Influence of surface chemistry on kinetics and degradation

- Development of in-situ methods for electrochemical investigations

Project Manager: Markus Valtiner

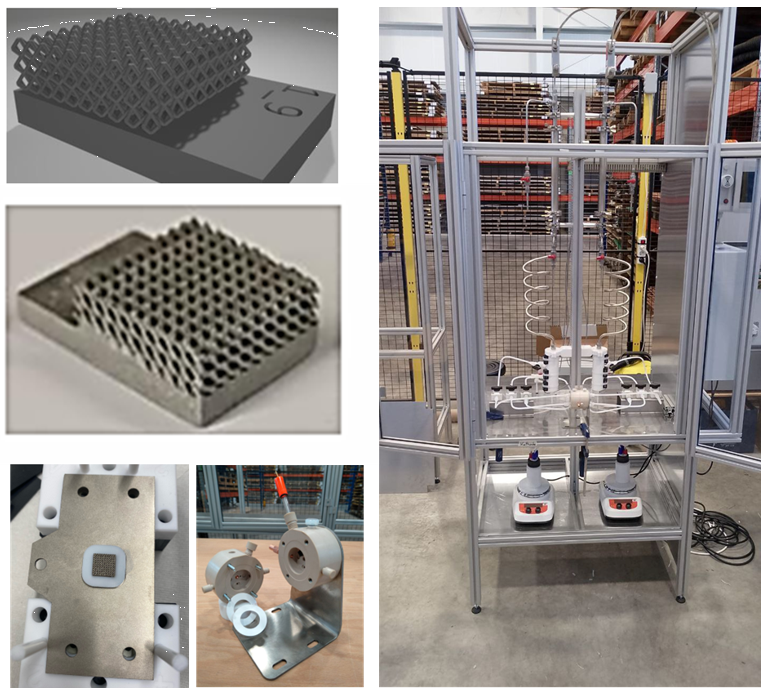

AktivMAT

Development and benchmarking of new active materials for H₂ and CO₂ electrolyzers for the production of green gases

The AktivMAT project developed and evaluated novel, additively manufactured electrode materials for H₂ and CO₂ electrolysis to produce green gases.

The goal was to optimize hierarchical 3D structures with regard to catalytic activity, stability, and techno-economic feasibility.

The results show that Ni and 316L electrodes produced by Laser Beam Melting (LBM) demonstrate improved gas bubble detachment, lower overpotentials, and high long-term stability (>600 h).

Techno-economic analyses confirm the competitiveness of these materials compared to conventional electrodes. Thus, AktivMAT provides an essential foundation for the industrial introduction of cost-efficient, sustainable electrodes for the production of green gases.

UMCAWE

In the UMCAWE project, the electrochemical conversion of CO₂ from industrial exhaust streams into methane was investigated – a key “power-to-X” process for the energy transition.

The focus was on the development of novel copper-based electrocatalysts, tests with real industrial exhaust gases, and the construction of an innovative medium-pressure demonstrator (up to 50 bar).

The results show: by using optimized Cu/ZrO₂ catalysts, high Faradaic efficiencies for methane could be achieved. Industrial exhaust gases that had previously been concentrated using amine scrubbing proved to be particularly well-suited for the process.

At the same time, techno-economic analyses confirm that CO₂ electrolysis with methane production can be efficiently integrated into existing value chains (e.g., biogas, cement).

With the successful construction of the unique pressure setup in Austria, important prerequisites for future industrial use were created. UMCAWE thus provides an essential foundation for the sustainable utilization of CO₂ emissions and the production of green energy carriers.