Area 1 – Functional Interfaces and Surfaces

The surface of a material has a great influence on many physical, electrical and chemical properties, so coatings or other surface treatments can strongly influence the component properties. Such properties include corrosion resistance, compatibility with the environment, optics, hardness, strength and electrical properties, among many others.

In the large field of functional surfaces and interfaces, CEST’s research and development work focuses on chemical, galvanic, and plasma-electrolytic deposition techniques and simultaneously on the related dissolution, polishing, and oxidation processes of surfaces. In addition, bonding technology and the necessary surface pretreatment as well as in-situ analytics for understanding interfaces also play a role in the research portfolio of the centre.

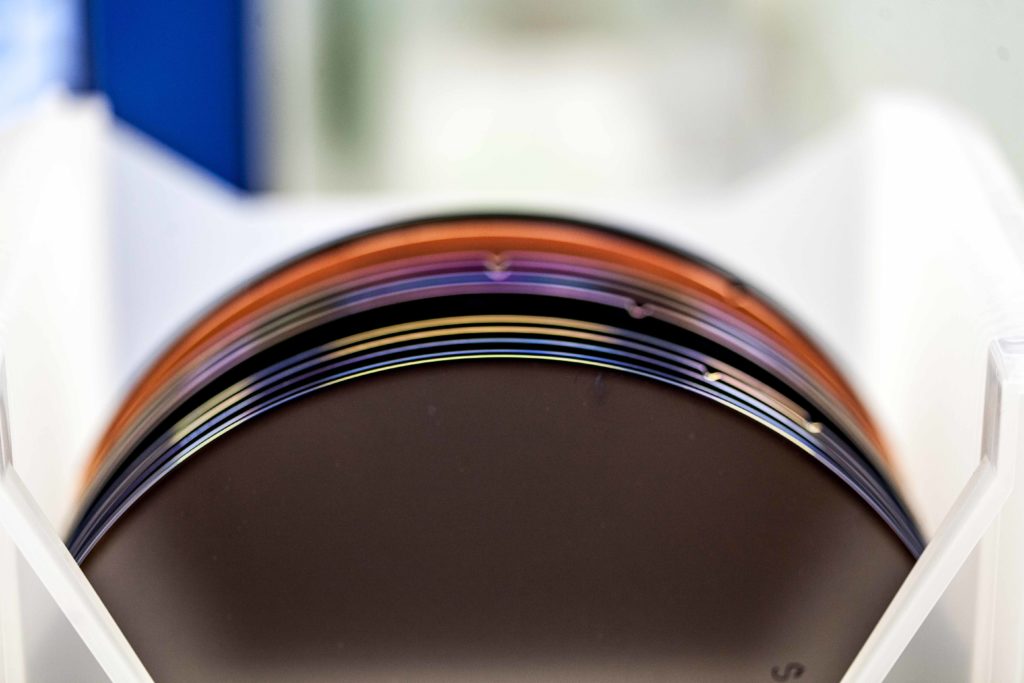

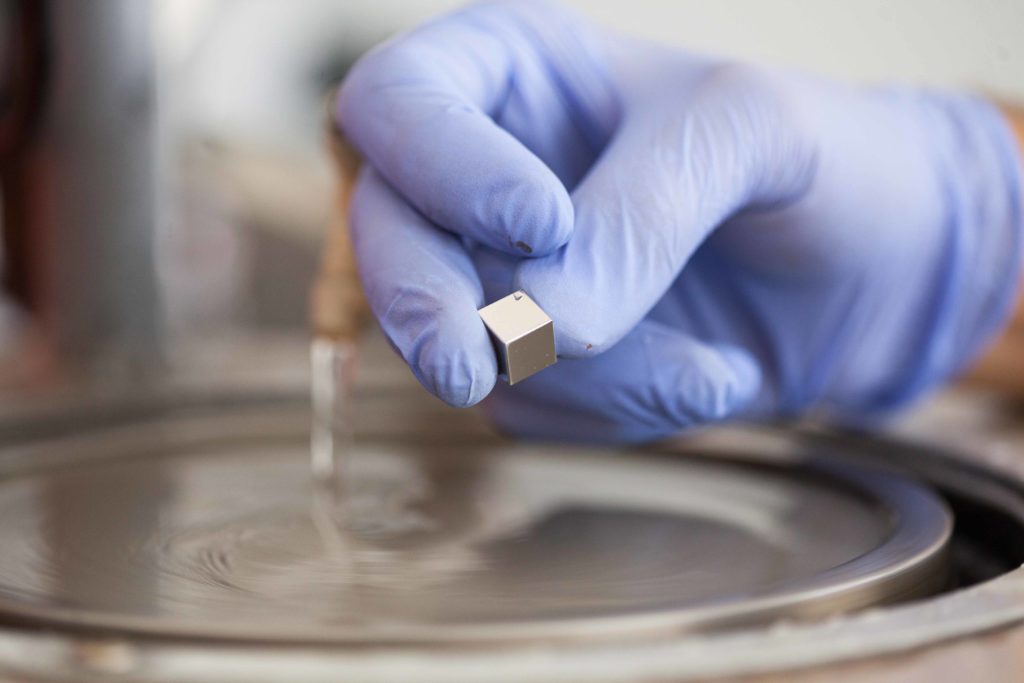

The chemical and galvanic deposition of metal layers can be a refinement of the surface but also a functionalisation of the same. Depending on the required combination of properties, the suitable coating material and the appropriate coating process must be selected. In addition to the classical galvanic coating of conductive components, autocatalytic processes can also be used to coat non-conductive or poorly conductive substrates, such as most plastics and various composite materials. We use this very successfully to metallise polymer-based, additive manufactured (3D-printed) components.

On the other hand, non-metallic surface layers can be produced or reinforced (e.g. by creating alumina or titania layers) by electrochemical processes and metallic materials can be polished (electropolishing) and shaped (electrochemical ablation) by targeted material removal.

Modern deposition processes for functional surfaces no longer work with just one substance, but produce composite systems with properties specially tailored to the application. New coating systems for corrosion and wear protection, as well as alloy deposition, co-deposition of coatings and nanoparticles and coating systems from non-aqueous electrolytes are examples of our work.

The investigation of adhesion mechanisms of adhesives such as epoxides and polyurethanes on metallic surfaces, also under the influence of corrosion, is also an important focus of research at CEST. Due to the increasing complexity of metallic coatings, well-tried adhesive systems often reach their limits. Therefore, it is important to understand the interactions of oxidic metal surfaces with adhesives and organic coatings. The knowledge gained helps to assess the suitability of new surfaces for bonding.

Electroplating technology has been a key industrial technology for decades and is used in many areas of application. A fundamental problem is the frequent use of toxic substances, the low level of knowledge about the exact deposition mechanisms and about the relationships between manufacturing conditions, coating composition, microstructure and the properties achieved, despite years of application experience. At the interface between industrial application and scientific research, CEST’s various projects in this field investigate fundamental interrelationships and use them to develop new, competitive processes. The results of this research ultimately enable our industrial partners to improve the technical properties of coatings in new processes, to introduce more cost-effective processes and, at the same time, to reduce the environmental risk of the processes and products.