In the glow discharge optical emission spectroscopy HF (GDOES-HF), argon atoms are ionized by means of high frequency in a hollow anode and accelerated in the direction of the sample (cathode). At the sample surface thereby atoms are knocked out and excited continuously. In the transition back to the ground state, characteristic light is emitted for each element, which is measured. Due to the continuous material removal, a depth profile analysis is possible.

Application:

- characterization of surfaces (quantitative depth profile analysis)

- determination of material composition (bulk analysis)

- available elements: Ag, Al, Au, B, Ba, Bi, C, Ca, Cl, Co, Cr, Cu, F, Fe, H, In, Ir, K, Li, Mg, Mn, Mo, N, Na, Nb, Ni, O, P, Pb, Pd, Pt, S, Sb, Si, Sn, Ta, Ti, V, W, Zn, Zr;

Applications:

- Testing of surface coatings

- Testing of surface treatments (pickling, nitriding, phosphating, etc.)

- Investigation of diffusion zones

- Corrosion tests – check of corrosion protection measures

- Quality control

Spezifikationen:

- Quantification with certified standards

- Simultaneous analysis of 41 (+1) * elements

- *Monochromator for analyzing an additional element

- Bulk analysis (ppm range)

- RF excitation for conductive and non-conductive specimens

- HDD – High Dynamic Rage Detector

Depth profile analysis:

- Sputtering rate correction

- Depth resolution about 10%

- Depth range: (10) 50 nm – 190 μm

Sample requirements:

- analysis area: Ø 2 or 4 mm

- sample diameter: > 15 mm

- sample chamber for smaller samples > 2 mm

- sample thickness: up to 40 mm

- flat surface

- low roughness

- “airtight” sample

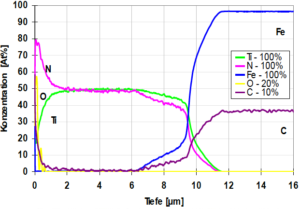

TiN on steel substrate

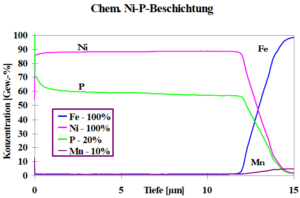

electroless Ni-P coating on steel substrate

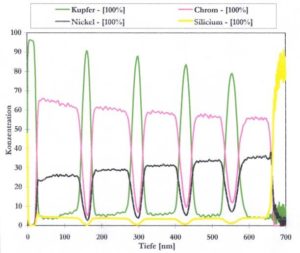

Cu/Cr/Ni-Multilayer on Si-Wafer